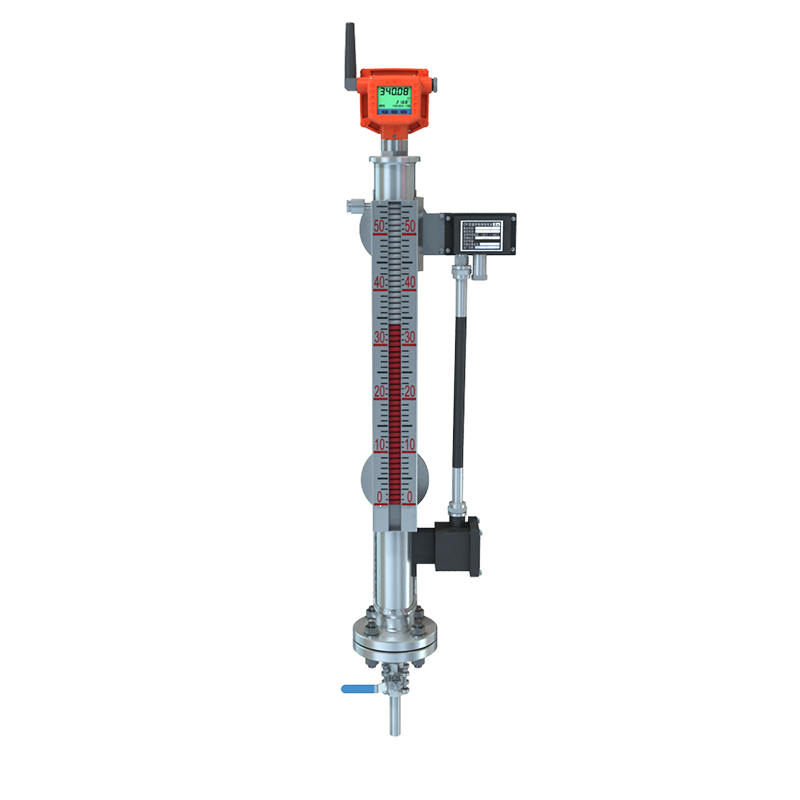

ACL Magnetostrictive Liquid Level (Soft Pole & Hard Pole )

Details

| Model | Magnetostrictive level meter ACL (optional twin floater) | |||

| Brief Introduction | ACL series magnetostrictive level meter is high-tech intelligent level meter that we research and develop according to the requirements of industrial field, and we adopt the technology of sensor signal processing, mathematical modeling, information operation and intelligent communication technology accumulation. This gauge adopts the magnetoctrictive theory and has the advantages of high precision, long linear range and absolute position measurement, which can measure the tank liquid level accurately. It also has the advantages of high precision, strong environment adaptability, high reliability, simple installation, convenient maintenance, which is widely used in petroleum, chemical, food, medicine, and other areas of the level measurement, and gradually replace the other traditional liquid level meter; it has been the first choice of the liquid level measuring instrument. | |||

| Measuring theory | When ACL series of magnetostrictive level meter sensor works, the sensor circuit part will inspire a pulse current on the wire waveguide, when this current diffuses along the waveguide, it will produce the impulse current magnetic field around the waveguide. Magnetostrictive theory, namely: strain pulse produced when different magnetic fields intersect, the detected time can calculate the accurate position of intersection. There is a float equipped outside sensor rod, this float can move up and down along with the change of the level. There is a group of permanent magnetic ring inside the float. When the impulse current magnetic field meet the circular magnetic field produced by float, the magnetic field around the float will change, so as to make the waveguide wire made of magnetostrictive materials produce a torsion wave pulse in float position, this pulse will be returned along the waveguide at a fixed speed and detected by the detection institution. By measuring the time lag between the pulse electric current and torsion wave, we can know the float location that is liquid height. Magnetostrictive liquid meter technology advantage: magnetostrictive liquid level meter is suitable for high precision requirement of clean liquid level measurement, precision can reach 1 mm, the latest product precision can reach 0.1 mm. | |||

| Application | various types of tanks used in oil storage and processing, such as flash tank, separator, etc. | |||

| liquid level measurement, control and monitoring field such as chemical industry, water treatment, pharmaceutical, electric power, papermaking, metallurgy, boiler, etc. | ||||

| Characteristics | high and low temperature resistance, corrosion resistance, friction resistance, resistance to high pressure | |||

| resistance to dust, can measure steam, can install belt material without stop working | ||||

| suitable for tank side mount, such as flash tank, separator, heating furnace level measurement | ||||

| the backlit LCD display, easy to field observation at night | ||||

| against lightning, anti-interference, explosion-proof design, used in flammable and explosive place | ||||

| intelligent real-time self-tuning, accurate, stable and reliable | ||||

| long service life, maintenance free, improve project quality and production efficiency | ||||

| Parameters | Measuring Range | 50-20000mm(customized) | Hard pole: 50-4000mm | |

| Soft pole: 4000-20000mm | ||||

| Accuracy grade | 0.2grade±1mm、0.5grade±1mm、1grade±1mm | |||

| Linear error | ≤0.05%FS | |||

| Repeated accuracy | ≤0.002%FS | |||

| Power supply | 24VDC±10% | |||

| Output signa | 4-20mA | |||

| Communication | RS485(Modbus RTU) | |||

| Operating Environment | temperature -30℃~70℃ | |||

| relative humidity: <90% | ||||

| barometric pressure 86-106KPa | ||||

| Medium temperature | -40~85℃ | |||

| Working pressure | ordinary pressure to 10MPa | |||

| Medium density | 0.5-2.0g/cm3 | |||

| Protection Degree | IP65 | |||

| Explosion-proof grade | ExdIIBT4 Gb | |||

| Install mode | Top mounting | Side mounting | ||

Our Advantages

1. Specializing in the field of measurement for 16 years

2. Cooperated with a number of top 500 energy companies

3. About ANCN:

*R&D and production building under construction

*Production system area of 4000 square meters

*Marketing system area of 600 square meters

*R&D system area of 2000 square meters

4. TOP10 pressure sensor brands in China

5. 3A credit enterprise Honesty and Reliability

6. National "Specialized in special new" little giant

7. Annual sales reach 300,000 units Products sold worldwide

Factory

Our Certification

Explosion Proof Certificate

Certificate of Patent

Customization Support

If the product shape and performance parameters have special requirements, the company provides customization.

Product Advantages Introduction

Utilizing the principle of magnetostriction, the ACL series level gauges offer numerous advantages that make them stand out in the market. First and foremost, it boasts exceptional precision, ensuring accurate readings even in the most critical processes. With its high accuracy, industrial operators can have complete confidence in the level measurements provided by this advanced tool.

Another distinctive feature of the ACL series is its long linear range. This means it can measure a wide range of liquid levels, making it suitable for a wide variety of tanks and containers. Whether you are monitoring liquid levels in large storage tanks or smaller vessels, this level gauge will provide accurate measurements over its entire range.

Additionally, the ACL series is designed to provide absolute position measurement. This means that it not only provides real-time liquid level measurement, but also indicates the exact location of the liquid in the tank. This invaluable feature enables precise control and monitoring, ensuring efficient management of industrial processes.

One of the key selling points of the ACL range is its adaptable design, with soft and hard stem options. The flexibility of the soft stem version makes the gauge easy to install and adjust for a variety of tank sizes and liquid types. On the other hand, the stiff stem version offers increased sturdiness, ensuring durability in harsh operating conditions. Environmentally demanding industries can rely on the hard rod ACL series to withstand rigors of operation.

In addition, the ACL series is also equipped with comprehensive intelligent communication capabilities, which facilitates seamless integration into existing industrial networks. Its advanced communication technology enables remote monitoring and control, making it an effective solution for process automation and optimization. Operators can remotely access real-time data and manage levels, improving operational efficiency and reducing manual intervention.